The Heart & Soul of a Mag Bay

A Review of our Construction Practice and Company Culture

In short time, the Mag Bay 33’ has disrupted the industry by raising the bar for craftsmanship, styling, and performance in the center console class.

Built entirely by a veteran team of former Cabo craftsmen, the boat is built with 100% vinylester resin, (including topsides) and we use fiberglass that is made in the USA. The use of over 80 molds provides for an incredible level of build quality that is simply unmatched and unprecedented.

The classic but modern styling of the boat has shaken the traditional square sided hull design. A swooping shear line follows into graceful aft tumblehome in the transom, providing a truly unique and refined look.

With its patented SVVT, twin step hull design by Michael Peters, the boat rides as good as it looks, providing a very agile yet solid feel at the helm.

But we went beyond using the best designer possible, using premium materials, and further than assembling the best boat building team we could think of. The real heart and soul of the Mag Bay 33’ is its quality. Our operation features a more tailored approach to building, selling and servicing boats than any competitor.

Its not often that companies get a chance to redefine a customers experience. Allow us to explain in detail on what makes a Mag Bay so special, and why our boats are redefining the status quo for quality in our industry.

Allow us to explain why we get out of bed every day, why we choose a no compromise approach to boat building, and why the Mag Bay is simply the best boat you will find in its class.

Sincerely,

Michael Howarth, President

Boat Building has Changed

As with everything in the last ten years, boat building has become more automated. With advances in composites, machining and computer technologies, boat builders and suppliers alike have increased access to practices and components that make boat building easier. This is great for the builders who want to build a boat via the kit route, but not so great for the customers who want a product of substance and true quality.

Quality & fit and finish.

We feel those words have been overused latley in the marine industry.

Mag Bay is on a mission to redefine what those Quality & Fit and Finish mean in our segment.

A Distinguished Look

The profile of the Mag Bay 33’ features a beautiful sheerline, but look close at the rub rail and you’ll notice there is no plastic or rubber cap in it. Most builders use a two piece rub rail because it is easier to fasten the steel rub rail and hide the deck joint, but his type of rub rail often takes away from the design and creates additional seams for saltwater to accumulate. We developed our hull and deck molds to directly accept rub rail involving no cap, and additionally the rub rail is hand formed. In the end, this leaves us with a more refined product and we are the only center console manufacturer using this process.

Unique Transom

Not only is the Mag Bay transom a design statement, it also adds to the strength of the boat. The transom is nearly 4” thick after we complete our production process with hand laid fiberglass + 2” thick high density foam core. Taking it a step further, the deck is bonded and faired at the round portion of the transom, so in theory there is no hull to deck joint aft. One could argue our transom construction integrity is superior to the traditional approach of a sandwich & fastened hull joint. Additionally, the aft tumblehome extension makes for great storage that runs deep into the transom. This transom storage is great for fenders and lines so those items don’t crowd valuable fishbox or other storage.

Minimalist Design

To accomplish achieving a the unique & flowing design we looked hard at detail. Most boaters have become accustomed to exposed screws on their boats.

After all, bought components and manufactured sub-parts do have to be affixed to the structure of the boat somehow. We challenged ourselves to rethink this approach. The moment you board a Mag Bay, you’ll notice the layout is clean and uncluttered. We carefully engineered the entire boat to mitigate exposed screw heads, which leaves design lines intact. In addition to creating a more refined product, eliminating exposed screws minimizes rust and exposure to leaks.

Worthy Hardware

The next thing you’ll notice upon boarding the boat is our oversized hardware. The custom door latch closure on our side entry door will feel like it belongs on a bank vault, and although the door itself only weighs about 20 lbs, the custom 14” hinge is rated for much more weight. A bit more on hinges, you’ll notice we use piano style hinges for every hatch on the boat, and every hatch is fit with oversized all stainless-steel gas shocks. Taking it a step further, we use custom stainless steel brackets for the ball fittings & mounts, solving the quintessential and inevitable failure of these parts that normally occurs all to often. Lastly, every hatch on the boat is fitted with a 1⁄2” bulb seal allowing for a quiet closure.

In the cockpit sole, you’ll see our custom scupper grates proudly claiming Mag Bay. Above the scuppers, you might take notice of the oversized cleats along with custom stainless steel hawse pipes. Looking aft, you’ll notice a custom transom plate which cleanly displays the engine & steering rigging. The plate even features a 1” hose spigot for easy engine flushing. Not are these components more robust, but all this custom hardware makes for a distinct feel of quality that will last.

Moving forward

The leaning post on the Mag Bay 33’ is another example of our design efforts.

It is also loaded with amenities and its shape also matches the hull lines appropriately. Adding to the unique shape, we incorporated a true, 3” toe kick for each console and optional forward seating. On the leaning post, you’ll notice that the toe kick is actually built into the deck, not the console parts themselves. As such, we minimized the caulking line on the deck. The toe kicks can be fitted with optional multi color LED lighting that creates a really nice atmosphere at night.

Below Deck

We’ve gone above and beyond the standard supplied fuel tanks.

Three tanks- with a combined capacity of 338 gallons are secured to the stringer grid, then foamed in place. The tanks themselves are built from 1⁄4” aluminum and are coated with an epoxy to mitigate corrosion.

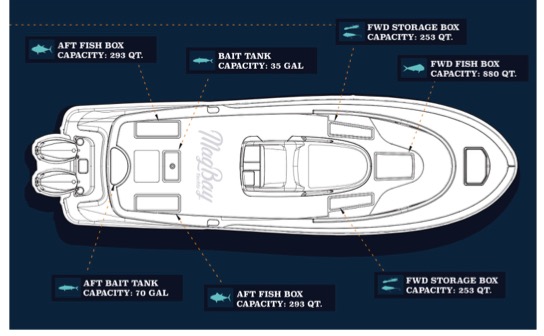

The rest of the deck features abundant fishbox storage.

Three insulated fishboxes come standard with each having an independent macerator. The forward fishbox is 7’ long.

Lazarrette

The lazarrete on the average boat can be likened to the space under a kitchen sink. It’s used for storage, and access to mechanical items that are often times mission critical, but in most cases not worried about. As a result, many builders don’t put pride in this area of the boat and the area is left cluttered with rigging of poor quality.

We’ve redefined what a “clean” lazarrete should look like.

The laz is finished off with bright white molded gelcoat and even incorporates non- skid. Throughout the lazarrette, you’ll notice that all hose clamps feature “clamp- aids”, an extra effort you wont find other builders taking. The way we have engineered the fitment of all components is simply striking, with everything fit in a purposeful and intuitive location.

The sea chest is necessary due to our stepped hull, and prevents the bait pump system from ingesting air. You’ll notice our sea chest features a thicker than usual cover with all stainless hardware. You might also notice our bait pumps are mounted on the outside of the seachest, which makes for easier replacement access in the event of failure.

Engineered Drain System

We went beyond using high quality through hull fittings and designed a common overboard drain. This setup allows the Mag Bay 33’ to have one through hull on each side of the boat instead of four on each side. The advantage is less stainless steel fittings on the waterline and a clean design.

Helm Area

Everything in the helm area is designed with intuition.

A black glass dash provides a clean look for up to two 17” MFD’s, and the optional teak adds adds warmth and creates a certain big boat feel.

Forward Console

Upon entering the forward console, you might notice the robust entry door. While others offer a flimsy acrylic door, our door is a foam cored fiberglass door with full length stainless steel piano hinge.

Sitting in the console facing aft, you’ll be greeted by the heart of the boat’s electrical system. Our wiring is simply unparalleled. This is the prime example of why on a very base level, you can be proud to own the best built boat. If you ever have an issue, the problem will be easily traceable as all wires are labeled and individually fused. We simply don’t cut corners and our wiring is hard proof.

A finished Anchor Locker

Another area of the boat we reinforced with quality is our anchor locker.

When you open the robust, gasketed hatch, an oversized gas shock and custom built, 14” stainless steel piano hinge act on providing the sense your dealing with very substantial equipment. The optional stainless windlass, (rated for 40’ boat), and the 316 stainless steel anchor mounted through the stem are ready to take on the ocean’s challenges that wait.

Tow Eye Challenge

With all its refinement, the Mag Bay 33 lends itself to be an excellent towable tender. As such, we’ve designed the optional bow tow eye to be integral to the core of the boat. The tow eye is made from 1” thick stainless steel and is heavily reinforced with steel inside the bow. We’d own to the challenge of suspending the boat up by the eye. No one has taken us up on the challenge yet, but Mag Bay tenders can be spotted throughout the Carribean.

Conclusion

Mag Bay is built upon over 40 years of boat building experience in creating only the best product possible. The company culture of quality permeates into everything we do, and the results of this proven approach are demonstrated in the 1000’s of award winning CABO’s & Pacific Seacraft boats built by the same team of passionate craftsmen and proudly owned around the world.

We have kept to our core principles of quality, craftsmanship and styling and introduced a new breed of center console boat, a breed that needs no apologies and makes no compromise, and breed where the right way is the only way.

So when looking for your next boat, remember to fully examine the details, determine if the boat has substance and rest assured that a boat produced by Mag Bay will simply be the best built boat you will find.